Implementing turn rate standards help reduce inventory by 30%.

26% improvement in overall productivity

Strategic Intent

Redesign the business model to stabilize sales losses, improve customer service, cut costs and return to profitability

Situation

- Mid-size distributor of packaging materials

- Revenues down 24% due to economic downturn

- Costs not adjusted to align with sales reductions, resulting in two years of losses

- New “turnaround” CEO has sense of urgency

- Other new senior managers learning to work together

Issues and Barriers

- Purchasing and sales process produces excessive and aged inventories

- Warehouse operations lack planning process

- Distribution infrastructure utilizes too many locations

- On-time customer deliveries at 92%, despite excess delivery capacity

- Customer support not aligned with customer demands

Key Implementations

- Remove sales from sourcing, pricing, input on customer demand and inventory levels

- Set ABC standards for inventory turn rates

- Outsource distribution activities

- Consolidation for warehouses and distribution centers

- Supervisory training & management effectiveness coaching

Results

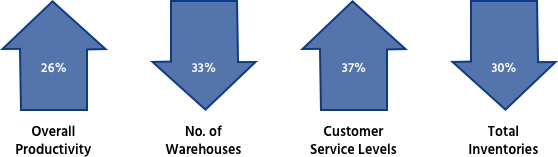

Seven-month Brooks International initiative completes with key results being realized. Client returns to profitability, achieving:

- 26% improvement in overall productivity

- 33% reduction in number of warehouses

- 30% reduction in total inventories

- On-time deliveries up from 92% to 98%

- Customer service levels up from 65% to 89%

Client Perspective

We have made a tremendous improvement in our operations, both from an execution and cost perspective. To a person, the Brooks team members were all very capable individuals and each made solid contributions to our operations.

— Chief Executive Officer