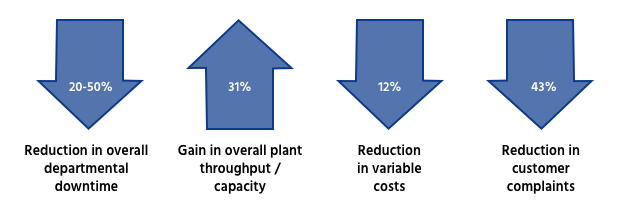

Downtime reduction fuels 31% gain in throughput and capacity.

12% in variable costs

Strategic Intent

Improve the overall utilization of plant assets and resources in order to gain much-needed production capacity

Situation

- Global billion-dollar specialty chemical producer

- 3,000 employees across five continents

- Holds leadership position in four business segments

- Industry experiencing growth in product demand

- Actively making capital investments to add capacity

- Newly acquired U.S. plant is under-performing and must optimize its available capacity

- Supply-chain issues also affecting customer satisfaction and inventory levels

Issues and Barriers

- Historic plant culture becoming a challenge

- Weak front-line supervision is part of the problem

- Management exhibits silo-like and fire-fighting behaviors

- Performance information not accurate or timely

- Core processes and management systems inadequate

- Excessive downtime throughout plant

- Maintenance is reactive rather than preventive

- Inconsistent production, planning, scheduling and control

Key Implementations

- Translate corporate goals to all levels

- Develop position-specific expert models with corresponding individual roles and responsibilities

- Design and install system for managing manufacturing, quality control and maintenance

- Conduct management and supervisory effectiveness coaching

- Design methods for capacity balancing and scheduling

- Install sustainable improvement process

Results

At the outset of the engagement, this plant was the company’s poorest overall performer. By the engagement’s conclusion, customer satisfaction improves dramatically and the plant’s performance ranks among the company’s best.

- The 20-50% downtime reduction, across departmental processes, results in 31% gain in throughput and capacity.

- 12% reduction in variable costs

- 43% reduction in customer complaints

Client Perspective

With the significant results achieved on this project as well as on previous collaborations with Brooks, I am pleased to recommend their services to any organization seeking performance improvement in a post-merger environment.

— Vice President, Operations