30% increase in maintenance productivity

Equipment downtime reduced 18%

Strategic Intent

Rapidly improve equipment utilization and operating consistency – and reduce production costs to save a poor-performing facility and 225 jobs

Situation

- Leading manufacturer of water transmission products, primarily ductile iron pipe and fittings

- $1.8 billion revenues in the United States, Canada and Australia

- Industry undergoing capacity consolidations

- After big investments, client’s poorest-performing plant still lags behind and faces likely shut down.

- EVP has keen sense of urgency about this initiative.

Issues and Barriers

- Attrition has led to many new supervisors

- Executive goals not communicated or understood

- Maintenance primarily fire-fighting without effective planning or parts inventory control

- Key metrics not linked to ownership or accountability

- Core processes fail to focus on manpower planning, production scheduling or overall resource utilization.

Key Implementations

- Establish and translate clearly defined SMART goals

- Redefine supervisory roles and responsibilities and support supervisors with one-on-one coaching

- Develop new metrics/measures with accountability

- Establish plant-floor disciplines and expected behaviors

- Develop expert models and best practices throughout

- Implement new comprehensive system for managing – focused on work planning/prioritization, preventive maintenance, manpower allocation and sustainable improvements

Results

Average Cost Per Ton Reduced 8%

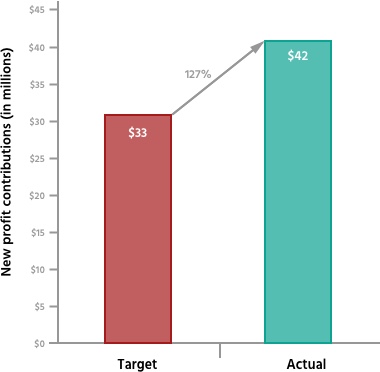

As a result of engagement, cost benefits and new profit contributions of $4 million are realized, representing 129% of the engagement goal. Of even greater importance, plant is still operative and the 225 employees are still working.

- 30% increase in maintenance productivity

- 18% reduction of equipment downtime

- 8% reduction in cost per ton produced

Client Perspective

Bringing the cost per ton down gives us the breathing room to keep this facility going and to continue working on improving its competitiveness by upgrading the operations.

— Executive Vice President