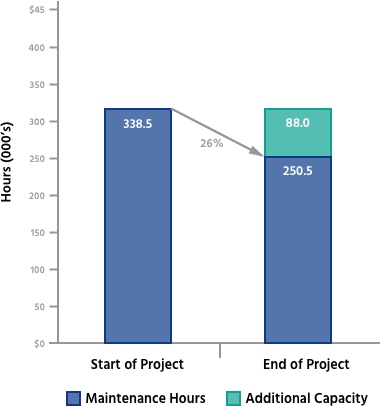

88,000 hours of capacity are created for improvement-focused maintenance.

Maintenance area utilization improves by 26%.

Strategic Intent

Achieve a 6-7% increase in commercial availability and net margin by improving maintenance practices and work capacity, including enhanced focus on preventive maintenance

Situation

- Division of $3 billion electric utility company

- Operates 20 power plants with generating capacity of nearly 9,700 megawatts

- Demand and price for electricity at an all-time high

- Top-performing generation facilities returning excellent profits

- CEO promised investors a commercial availability performance level of 91%

Issues and Barriers

- Inability to effectively plan, schedule, execute and complete work management tasks

- Recently adopted SAP; work management not being utilized correctly

- Lack of recognition of deficient maintenance practices and their resultant impact on commercial availability

Key Implementations

- Maintenance system for managing support of the SAP system process and capabilities

- Organizational design for the facilities including position-specific expert models and individual accountability

- Supervisory and management effectiveness coaching

Results

Created 88,000 Hours of Capacity for Additional Availability Improvement-Focused Maintenance Work

- Maintenance area utilization improved by 26%, reflecting annualized monetary value of $4.3 million

- Additional maintenance time freed up to focus on preventive maintenance activities

- Installed effective measures to sustain improved levels of performance

- Improved material conditions at plant and reduced plant downtime

Client Perspective

This project has highlighted the real opportunity we have, within our control, to improve commercial availability, and has given us the tools to get there.

—Chief Operating Officer