Strategic Intent

To create an organization with consistent and reliable processes, management behaviors and decision-making that accelerates operating income to 25% within three years

Situation

- $3 billion global supplier of aerospace systems and components, serving a broad spectrum of the aviation industry worldwide

- 64 operating locations that design, engineer and manufacture aerospace systems

- Key U.S. facility with significant growth potential has both declining customer service and poor financial performance (O.I. only 7%)

- Internal corporate efforts have failed in this facility

- President/COO has keen urgency around the change process

Issues and Barriers

- Degenerating state of costs, customer service and quality that is jeopardizing future orders and new business growth opportunities

- On-time customer product delivery less than 50%

- Attitudinal and behavioral issues, lack of skills/training, communications breakdowns and poor process controls, all contribute to the dysfunctional nature of this facility

- Consistent reactive fire-fighting is the plant management’s style

Key Implementations

- Translated and aligned SMART goals across all organizational levels

- Developed and implemented a comprehensive, proactive System for Managing (SFM) that is focused on production scheduling and capacity planning

- Established goal achievement review process linked to new SFM

- Enhanced sales process to drive business plan realization

Results

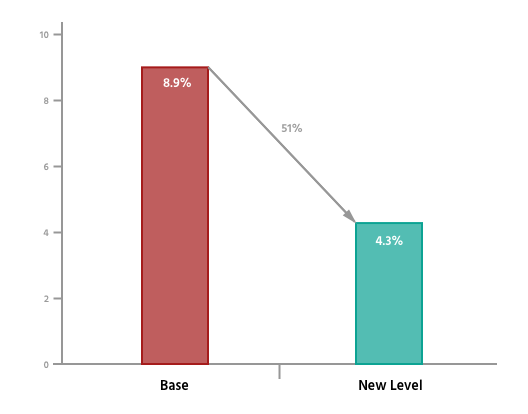

Cost of Quality Reduced by 51%

- Financial results are an overall annualized improvement of $4.1 million, which is translated to an operating income ratio of 16%, up from the prior year’s level of 7%, a big year-one step toward the three-year O.I. goal of 25%

- Shop floor productivity improved by 48%, contributing $1.8 million to the new O.I. level

- Cost of quality due to scrap, rework and product defects was reduced by 51%, from 8.9% to 4.3%, of sales, another significant income contributor

- Reduced past-due backlog hours by 25%, from 16,500 hours to 12,200 hours, improving revenue flow and customer satisfaction

Client Perspective

Things are moving in the right direction in [plant location].

— President & COO

I can attest to the change in behaviors in [plant location].

— Division President