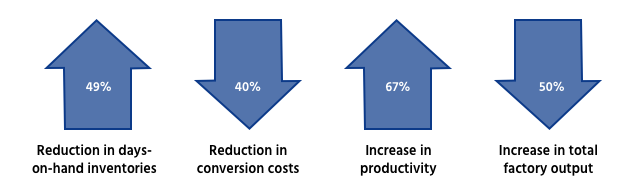

Factory conversion costs reduced by 40%

50% increase in total factory output

Strategic Intent

Significantly reduce factory conversion costs to grow volume and improve revenues while simultaneously improving on-time customer deliveries and employee satisfaction

Situation

- Computer manufacturing division of major telecommunications company

- Division recently acquired through merger, and post-merger cultural issues exist

- Employee concerns about plant and their future

- Competition and commodity pressure is intense

- Dozens of internal performance improvement programs attempted but not integrated

- Low-cost producers will “win the war”

- New general manager serious about “winning;” and future of this unit hinges on turnaround

Issues and Barriers

- Factory conversion costs are out of control and delivery performance is totally unacceptable

- Extremely high employee dissatisfaction

- Invalid production data prevents accurate scheduling and performance reporting

- Schedule breaks and misses, late starts and delayed shipments are routine occurrences

- Cost to manage comparatively excessive

- No clear employee performance goals or feedback

Key Implementations

- Develop and translate extensive set of performance goals and standards

- Design and implement quantitative capacity modeling and planning system

- Design new shop floor planning and scheduling system that matches resources with demand

- Redesign both management and indirect structures to improve plant floor support and reduce costs

Results

Key Project Results

Beyond the impressive list of results from this initiative – employee satisfaction improves to the extent that turnover drops dramatically – coupled with absenteeism reduction of 48%. General manager reports total annualized financial benefits directly attributable to engagement are in excess of $8 million.

- 40% reduction of factory conversion costs

- 50% increase in total factory output

- Days-on-hand inventories reduced 49%

- 85% improvement in on-time deliveries

- Plant-wide productivity increases 67%

Client Perspective

During our project with Brooks, we far exceeded both our productivity and quality goals in only eight months. Brooks has been a reliable, hard working ally in our efforts to improve our competitive position and I would recommend their use to all who face similar change requirements.

— Vice President & General Manager